Get The Most Out of Tire Performance

Get The Most Out of Tire Performance

Purcell has been at the forefront of retreading innovation for over 50 years. We understand the challenges you face. Our exceptional retread processing lead by state of the art capabilities are designed to provide the following:

Reduce Unscheduled Down time

Reduce

Costs

Improve Operational Readiness

WHY YOU SHOULD BUY RETREAD TIRES

Innovative tire retreading tools and manufacturing methods continuously improve quality and cost savings

Steps of Purcell® MRT Retreading Process

At Purcell Tire, We use the Purcell® MRT Process in our Retreading Plants.

Initial Inspection

Every casing, every detail, inspected every time – Enables trained operators to detect subtle irregularities that may indicate internal damage such as zippers.

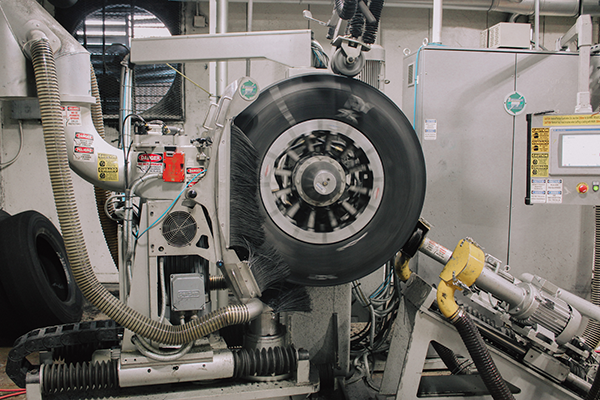

Buffing

Computer automated, guided by casing-specific database and sensors – Provides under tread of optimal profile, depth, and texture.

Casing Integrity Analysis (CIA)

SHEAROGRAPHY – Two-step laser photography performed on every tire -Reveals belt separations or blisters within the belts or other areas that may not be visible.

X-Ray

Available and used when needed – Allows visual inspection of the steel belts within the casing

Repair

Best practice repairs – Thermal curing along with mechanical pressure exceeds industry standards.

Tread Building

Uses PURCELL® tire tread – Combines two operations into one: applying hot cushion gum and pre-molded tread.

Double-Enveloping

Unique use of inner envelope applies pressure to both sides of the repair – Ensures every surface of the retread undergoes uniform pressure and temperature.

Curing

Computer controlled for minimum temperature variations – Achieves optimal uniformity and enhances full integration of all repairs.

Final Inspection

Assurance of the best retread every time – Thorough inspection of crown, sidewall, bead and interior – we make sure your retread is for the road.

Advantages of State-of-the-Art Equipment

Purcell knows that preparing a casing for retreading is an exact science. The visual inspection of a used truck tire is not enough to make sure all the flaws and nail holes have been detected.

Safety is a BIG Benefit When Retreading Tires – Extending Tire Casings Life

We perform critical pressure testing on each and every casing to verify radial sidewall strength. Different inflation pressures are used during the inspection stages. Inspecting a casing under pressure helps to identify tread and casing separations, missed repairs, other tire deformities and off-center treads.

Exact Manufacturing Standards

All tire casings have to meet exacting standards of proper structural integrity before they can be retreaded. If casings are properly maintained the “essence” of the tire doesn’t experience the level of wear that tread does, so it is perfectly safe when new tread is molded over used tire casings. Retread tires undergo innovative manufacturing processes with state of the art tools and technology to continuously improve quality and cost efficiencies.

Rigorous Quality Control

It takes specialized equipment, modern technologies, and experienced people to service the tire retread industry. We have decades of experience in the repair and retreading of all types and sizes of commercial tires. Our commitment to reducing your tire costs starts with quality control to maximize the useful life of your tires. Simply put Purcell offers the best methods and expert back-up to extend tire life and reduce your overall cost per mile.

Proper Fit and Finish

Starting with product analysis, testing and evaluation and proper tire selection Purcell offers retreading services and management that help streamline your tire program and keep you rolling at peak performance, so you can focus on your core business. We tailor individual programs to enhance consistency across the entire spectrum of your service and maintenance needs.

Continuous Investment

Time is money to fleet managers and individual truck owners. Retread tires are a good choice and perform equal to most new tires. Purcell has continuously invested in critical retread manufacturing technology. This commitment extends to each of every tire that goes through our process. You can also expect great pricing and great quality on retreads from Purcell.

Purcell Also Retreads the Largest Tires in the World

We are a world leader in OTR tire service, repair and retreading. Just ask any of our customers who have BIG wheels. Purcell has the equipment, experience, and people to keep ALL equipment rolling.

Purcell can handle

ALL SIZES PERIOD!

A world leader in OTR tire service, repair and retreading. Purcell has the equipment, experience, and people to keep all equipment rolling.